Newsletter LEAD Cohort 9

INDUSTRIAL ECOLOGY:

TOWARDS A SUSTAINABLE INDUSTRY SYSTEM,

EXPERIENCES OF PT. NATIONAL GOBEL

Novian Imamsjah Roesli, PT. National Gobel

Summary.Industrial ecology is a pattern of interrelation among industrial activities, which includes mining, farming, fishery, energy, manufacturing and service providing. It adopts the interrelation pattern among organisms in the natural ecological system. In nature, all organisms interrelated with each other in a complex food chain as producers and consumers. An organism is other organism's food and an organism's waste is also other organism's food. In other word, as whole the natural ecological system is 100% efficient process. There is no such thing as waste. Industrial ecology is a nacent concept. There is no activity in this world yet, that fully adopt industrial ecology concept. But, nonetheless, there are trends toward this paradigm. Most of them are private sectors's iniciatives. In Indonesia, PT. National Gobel is well known for their environmental performance. Obtained the ISO 14001 certiffication in 1998 is an example. During their production techniques development, PT. National Gobel reflecting some principles of industrial ecology, which are can be developed further.

Summary.Industrial ecology is a pattern of interrelation among industrial activities, which includes mining, farming, fishery, energy, manufacturing and service providing. It adopts the interrelation pattern among organisms in the natural ecological system. In nature, all organisms interrelated with each other in a complex food chain as producers and consumers. An organism is other organism's food and an organism's waste is also other organism's food. In other word, as whole the natural ecological system is 100% efficient process. There is no such thing as waste. Industrial ecology is a nacent concept. There is no activity in this world yet, that fully adopt industrial ecology concept. But, nonetheless, there are trends toward this paradigm. Most of them are private sectors's iniciatives. In Indonesia, PT. National Gobel is well known for their environmental performance. Obtained the ISO 14001 certiffication in 1998 is an example. During their production techniques development, PT. National Gobel reflecting some principles of industrial ecology, which are can be developed further.

1. Industrial Ecology Definition

One of the more radical approaches to achieving greater levels of material and energy resource use efficiency involves the concept of industrial ecology. Garedel and Allenby define industrial ecology as follows:

Industrial ecology is the means by which humanity can deliberately and rationally approach and maintain a desireable carrying capacity, given continued economic, cultural, and technological evolution. The concept requires that an industrial system be viewed not in isolation from its surrounding systems, but in concert with them. It is a system view in which one seeks to optimize the total materials cycle from virgin material, to finished material, to component, to prdouct, to obsolete product, and to ultimate disposal. Factors to be optimized include resources, energy and capital.

In short, industrial ecology refers to the exchange of materials between different industrial sectors where the 'waste' output of one industry becomes the 'feedstock' of another.

2. Industrial Ecology Model System

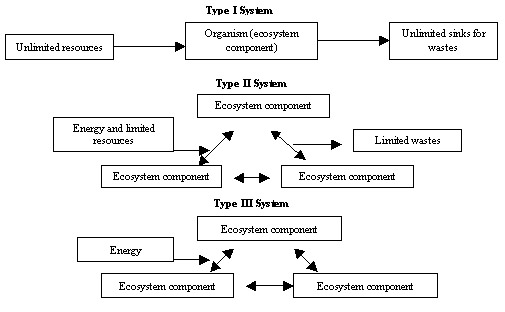

The concept of industrial ecology can be illustrated by considering three models of systems, based on the biological analogy. First system called Type I system, which might have existed early in Earth's history. At that time, usable resources were so lage and the amount of life so small that the existence of life forms had essetianlly no impact on avaliable resources. Virgin materials enter the system, are used only once, and are then disposed of as waste.

As the early life forms multiplied, external contraints on the unlimited sources and sinks of the linear system began to develop. These contrainst led in turn to the evolution of biotic system as an alternative to linear materials flows. Feedback and cycling loops were developed as scarcity drove the process of change, Type II system. In such systems, the flows of material within the proximal domain could have been quite large, but the flows into and out of that domain eventually were quite small. This system is much more efficient than the previous one, but it clearly is not sustanable over the long term because the flows are all in one direction, that is, the system is "running down".

The evolution of Type II system continued and led the change of ecosystem components and material flows into more complex and ultimately sustainable state. Biological ecosystems have evolved over the long term to almost completely cyclical in nature, with "resources" and "waste" being undefined, because waste from one component of the system represents resources to another. Note, that the exception to the cyclicity of the overall system is tah energy (in form of solar radiation) is avaliable as an external resource. This cyclical system (Type III), should for many material streams and products, be the goal.

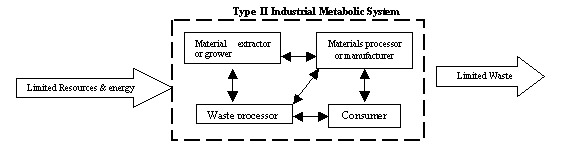

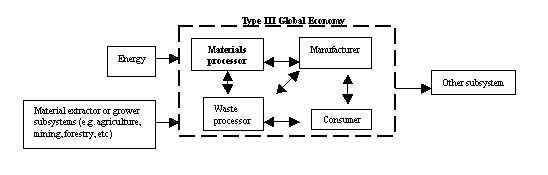

Industrial ecology, in its implementation, is intended to accomplish the evolution of manufacturing from Type I to Type II and ultimately to Type III.

The ideal evolution of industrial metabolic system will lead to state of global economy in which materials cycle within firms, sectors, and the economy as a whole. It is thus closed with regard to materials, but like the earth itself, open energetically.

3. Principles of Industrial Ecology

1. Products, processes, services, and operations can produce residuals, but not waste.

2. Every process, product, facility, connstructed infarstucture, and technological system should be planned to the extent possible to be easily adapted to forseeable, environmentally preferable innovations.

3. Every molecule that enters a specific manufacturing process should leave that process as part of a saleable product.

4. Every erg of energy used in manufacture should produce a desired material transformation.

5. Industries should make minimu use of materials and energy in products, processes, services, and operations.

6. Materials used should be the least toxic for the purpose.

7. Industries should get most of the needed materials trough recycling streams rather than trough raw materials extraction, even in the case of common materials.

8. Every process and product should be designed to preserve the embeded utility of the materials used.

9. Every product should be designed so that it can be used to create other useful products at the end of its current life.

10.Every industrial lanholding, facility, or infrastructure system or component should be developed, constructed, or modified with attention to maintain or improving local habitats and species diversity, an to minimize impacts on local or regional resources.

11. Close interactions should be developed with materials suppliers, customers, and representatives of other industries, with the aim of developing cooperative ways of minimizing packaging and of recycling and reusing materials.

4. Walking the talk: PT. National Gobel experiences

PT. National Gobel is a manufacturing industry who produces electronic devices and home appliances. PT. National Gobel is established in 1970 and since 1977 is declaring its concern to environmental issues. Since that moment, PT. National Gobel has done some environmental activity such as tree plantation, building pollution prevention devices, establishment of environmental and safety (EPPO&OSH) department, design of environmental friendly products, ISO 14001 certification and supporting government environmental activity.

The reason of all those efforts concerning the environment is because the company wants to minimize the effect to the environment caused by the product and the production process. This is based on the concept that human should live side by side with its environment. The driven force to enhance the environmental management efforts comes from the company itself, parent company requirements, government requirements and other requirements concerning the globalization era.

The concept of environmental management implemented is the integration of environmental activity into the production activity within the company. According to this concept, now environmental activity has become part of the company's daily activity. The environmental activity in PT. National Gobel is not only using end-of-pipe approach but also up-pipe approach. It means that the company is now starting the action to prevent the pollution.

Environmental activity in PT. National Gobel can be categorized into activity concerning environmental protection, resource conservation, chronic risk reduction and accident prevention. It means that environmental activity also compromises safety and health activity. By now, this activity starts to change from doing curative action to doing preventive action. This preventive action consist of the effort of material usage reduction, metal recycling, packaging recycling, hazardous material usage reduction and substitution, natural resources conservation, working area design that meets the environment and safety requirements and environmental friendly product development.

Although environmental activity has benefits, but it wasn't gained so easily. There are still some obstacles to do it perfectly. Some of the obstacles are low awareness for environmental protection and pollution prevention, no available technology that meet the company's needs and lack of information and resources.

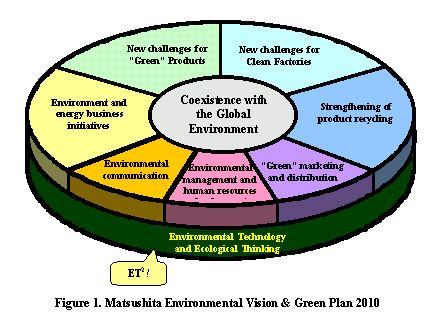

In the coming years, PT. National Gobel has set up some activities that hopefully will bring the company performance towards a better condition. These continuous activities is brought in form of PT. National Gobel Environmental and Occupational Safety & Health Master Plan which is a part of Matsushita's Environmental Vision and Green Plan 2010.

References

1. Graedel, T.E.; Allenby, B.R., Industrial Ecology, Prentice Hall, Englewoods Cliffs, New Jersey 07632, 1995.

2. Fiksel, Joseph; Design for Environment: Creating Eco-Efficient Products and Processes, McGraw-Hill, 1996.

3. Socolow, R; Andrews, C; Berkhout, F. and Thomas, V., Industrial Ecology and Global Change, Cambridge University Press, 1994.

4. Allenby, Braden R., Industrial Ecology: Policy Framework and Implementation, Prentice Hall, Upper Saddle River, New Jersey, 07458, 1999.

.***